Avoid costly mistakes with precise fibre testing equipment protocols

Avoid costly mistakes with precise fibre testing equipment protocols

Blog Article

Exploring Advanced Techniques in Fiber Measurement and Their Market Impact

In today's textile sector, accurate fiber measurement is vital for maximizing manufacturing processes and meeting sustainability goals. With the increase of cutting-edge imaging and logical devices, you can obtain much deeper insights right into fiber framework and make-up. This shift not only improves effectiveness however also straightens with industry standards. As these advanced techniques evolve, you might ask yourself just how they can better change making methods and effect the future of fabrics.

The Importance of Accurate Fiber Measurement in Fabric Manufacturing

Innovative Imaging Technologies for Fiber Analysis

When it concerns fiber analysis, cutting-edge imaging innovations are game changers. High-resolution microscopy strategies and spectroscopic evaluation methods provide you with comprehensive understandings into fiber framework and structure. These improvements not only boost accuracy however also streamline your measurement procedures.

High-Resolution Microscopy Techniques

High-resolution microscopy strategies have actually reinvented fiber analysis, allowing scientists to picture fibers at unprecedented levels of detail. With methods like scanning electron microscopy (SEM) and transmission electron microscopy (TEM), you can observe fiber morphology, surface functions, and cross-sections with impressive quality. These strategies enable you to compare various fiber kinds and analyze their architectural stability. You'll find that high-resolution imaging aids determine defects, additions, and other crucial characteristics that can affect material efficiency. Furthermore, advancements in electronic imaging software application have actually improved image processing, making it easier to examine and interpret information. By adopting these ingenious techniques, you can drive higher precision in fiber measurement and add to developments in numerous industries, from fabrics to composites.

Spectroscopic Analysis Methods

Spectroscopic evaluation methods have actually become powerful tools for fiber characterization, providing insights that enhance high-resolution microscopy. You can utilize techniques like infrared (IR) spectroscopy, which helps recognize the chemical make-up of fibers by determining molecular resonances. Raman spectroscopy uses another layer of detail, permitting you to examine molecular structures through spreading of single light. These methods not only enhance your understanding of fiber homes yet additionally enable the detection of pollutants and structural variants. By incorporating spectroscopic strategies with traditional microscopy, you acquire a much more extensive sight of fibers' physical and chemical characteristics, increasing your research study precision. Inevitably, these technologies can significantly influence product option and quality assurance in various industries.

Advanced Analytical Equipment and Their Applications

As you discover the domain name of fiber dimension, you'll uncover that innovative logical devices play a necessary duty in boosting precision and performance. Strategies like high-performance fluid chromatography (HPLC) and gas chromatography (GC) enable you to assess fiber make-up with remarkable accuracy. These devices allow you to identify particular elements and contaminants, ensuring quality control in your products.Additionally, using scanning electron microscopy (SEM) offers you a thorough view of fiber structure, assisting you understand just how different treatments affect performance. Modern software program likewise improves information evaluation, making it much easier to interpret complex outcomes and work together across groups.

Effect of Fiber Measurement on Manufacturing Effectiveness

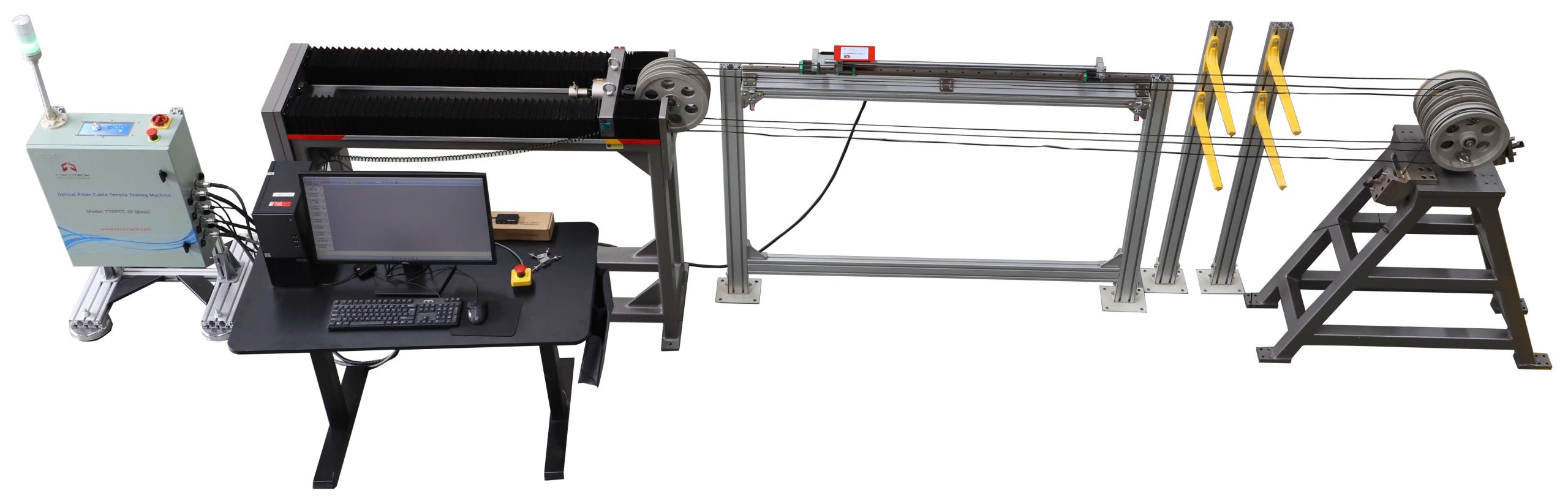

While precise fiber dimension might look like a small detail, it substantially impacts manufacturing performance in the textile industry. When you purchase exact fiber measurement methods, you can maximize basic material use and minimize waste. This brings about better resource allowance, allowing you to produce top notch materials without excessive using resources.By understanding fiber attributes, you can customize production processes to certain materials, enhancing your workflow and reducing downtime. As an example, understanding the specific tensile toughness of fibers allows you adjust equipment settings for maximum performance. This not only speeds up manufacturing yet additionally guarantees consistent product quality.Moreover, accurate fiber measurement assists you recognize concerns early in the assembly line, protecting against pricey reworks and hold-ups (fibre testing equipment). In general, applying sophisticated fiber dimension methods enhances operations, improves efficiency, and inevitably raises productivity. In today's open market, every information counts, and accurate fiber dimension is a game-changer

Sustainability Considerations in Fiber Evaluation Techniques

When you assess fiber, it's vital to contemplate lasting practices that can reduce ecological influence. Making use of environment-friendly measurement techniques and reducing waste in your evaluations can significantly improve your total sustainability. In addition, integrating lifecycle analysis right into your strategies can supply a more clear image of your fiber's ecological impact.

Eco-Friendly Measurement Approaches

Taking into consideration the growing index demand for sustainability in different markets, embracing green measurement approaches for fiber analysis has come to be necessary. You can start by discover this info here making use of non-toxic solvents and eco-friendly materials in your screening processes. These options not only lower ecological impact yet likewise boost safety for your group. Executing digital measurement techniques can better reduce waste, as they frequently need less physical examples and sources. Furthermore, leveraging ingenious innovations like near-infrared spectroscopy can yield precise results without hazardous chemicals. By selecting these greener approaches, you contribute to a more sustainable future while maintaining high standards in fiber high quality. Eventually, incorporating green techniques into your fiber assessment not just straightens with customer worths but additionally enhances your brand name's credibility.

Reducing Waste in Analysis

To efficiently reduce waste in fiber evaluation, you can apply strategies that improve your testing procedures and minimize resource consumption. Begin by enhancing sample sizes; using smaller examples can yield precise outcomes while saving products. Next off, invest in multifunctional equipment that permits different tests without needing multiple gadgets, lowering energy and resource use. You should also think about embracing electronic tools for information collection and evaluation, which can minimize paper waste and enhance efficiency. Consistently training your group on lasting methods ensures every person's aboard with waste decrease objectives. Lastly, teaming up with providers who prioritize sustainability can even more boost your efforts, enabling you to assess fibers while maintaining a dedication to ecological responsibility.

Lifecycle Analysis Combination

Incorporating lifecycle evaluation (LCA) right into fiber evaluation techniques can significantly enhance sustainability initiatives. By taking a look at the ecological influences of fibers from manufacturing to disposal, you can identify areas for enhancement. This approach aids you comprehend resource consumption, energy use, and waste generation throughout the fiber's life.When you incorporate LCA, you're not just measuring fiber features; you're additionally thinking about the ecological impact. This alternative view enables you to make informed choices that focus on sustainability. You could select fibers that need fewer sources or have a reduced carbon impact. Ultimately, LCA encourages you to enhance procedures, decrease waste, and advertise environmentally pleasant selections in fiber production, aligning your exercise with worldwide sustainability goals.

Industry Criteria and Laws Forming Fiber Measurement

As the demand for high-grade fiber items expands, understanding the market requirements and laws that regulate fiber measurement ends up being necessary. These standards assure consistency, accuracy, and safety in the measurement procedure, which inevitably influences item high quality. Organizations like ASTM International and ISO stated standards that makers need to stick to, covering various aspects such as fiber identification, toughness testing, and dampness content evaluation.

Future Trends in Fiber Measurement and Textile Production

Exactly how will advancements in modern technology improve fiber measurement and fabric production? You'll see a change toward visit this site right here automation and real-time data analysis, boosting accuracy and performance. Smart sensors will certainly keep track of fiber homes continuously, allowing for instant modifications in production. This suggests you can anticipate better fabrics with less waste.Moreover, AI and maker discovering will forecast patterns in customer choices, enabling makers to adjust rapidly. optical measurement system. By integrating blockchain innovation, you'll have much better traceability of materials, ensuring sustainability and honest sourcing.Virtual truth and increased truth will certainly play a role too, offering immersive training experiences for workers on fiber handling and production processes.As you welcome these changes, the textile industry will change right into a much more responsive, sustainable, and ingenious market, setting brand-new criteria for high quality and performance. The future of fiber dimension and fabric manufacturing is intense, and it's time to hop on board

Often Asked Concerns

What Are the A Lot Of Typical Fiber Types Measured in the Market?

In the market, you'll usually come across all-natural fibers like cotton and woollen, along with synthetic alternatives such as polyester and nylon. Each kind has unique residential or commercial properties, impacting their dimension and application in numerous products.

Exactly How Do Fiber Measurements Influence Consumer Item High Quality?

Fiber dimensions straight influence customer item top quality by guaranteeing consistency, longevity, and performance. When you understand these metrics, you can make informed options, causing enhanced complete satisfaction and better overall experiences with the products you utilize.

What Training Is Needed for Fiber Dimension Technicians?

To end up being a fiber dimension technician, you'll need customized training in textile scientific research, measurement strategies, and tools operation. Hands-on experience and certifications can improve your skills, making you efficient in exact fiber analysis and quality control.

Are There Any Type Of Accreditations for Fiber Measurement Professionals?

Yes, there are qualifications for fiber dimension specialists. You can go after choices like the Certified Optical Fiber Professional (CFOT) or numerous industry-specific credentials that improve your competence and credibility in fiber dimension and screening.

How Can Small Companies Apply Fiber Measurement Techniques Effectively?

You can carry out fiber dimension techniques properly by buying budget friendly devices, training your team, and developing clear protocols. Work together with market experts and constantly improve your procedures to boost accuracy and effectiveness over time.

Report this page